A garage floor coating can look great on day one, but how it performs over the years depends significantly on how the concrete was prepared before application. This step is critical, and the details matter.

If the concrete is too smooth, the concrete coating has nothing to really grab onto. If it’s too rough, it’s kind of like sticking a giant sticker onto a pile of gravel — adhering to the surface is tough.

Here’s how it works.

The CSP Scale Explained

The Concrete Surface Profile (CSP) is a rating system that measures the texture of a floor:

- CSP 1 = as smooth as it gets

- CSP 10 = very rough

- Target for garage floor coating = CSP 3–4

- Why this range is important:

- Too smooth (CSP 1–2): Coatings may lift or peel.

- Too rough (CSP 5+): Creates unnecessary roughness and doesn’t improve performance.

- Just right (CSP 3–4): Provides strong adhesion without damaging the floor.

Ways to Prep Concrete

Contractors have multiple methods to change the surface profile, but results vary:

- Acid etching → leaves concrete too smooth

- Low-pressure water jetting → also too smooth for long-term results

- Sandblasting / rotomilling → overly aggressive, creates excess texture

- Grinding → most effective, delivers CSP 3–4 consistently

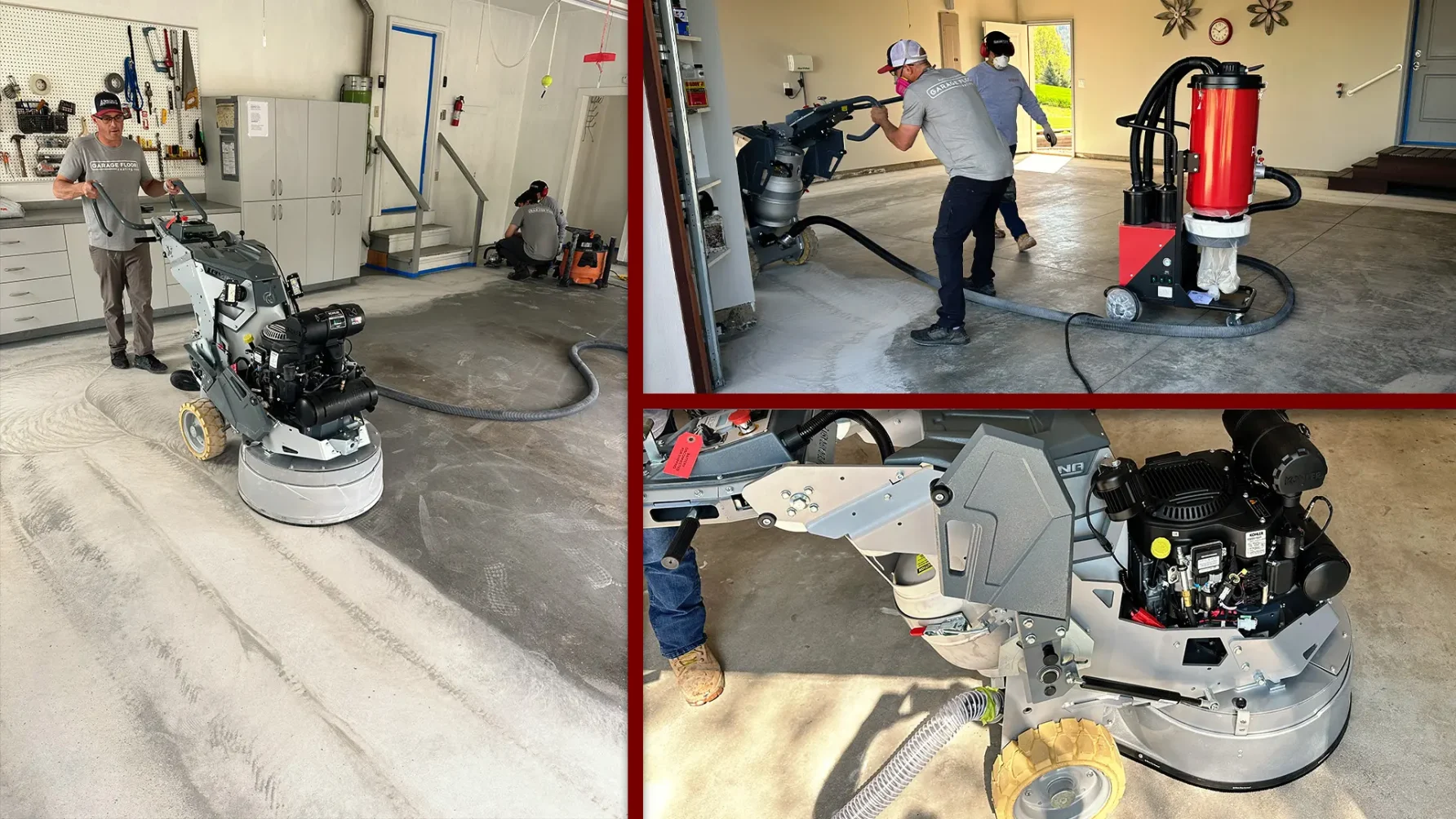

Propane vs. Electric Grinders

Another important factor is the type of grinder used:

Propane grinders

- More powerful and faster

- Cover large areas efficiently

- Don’t require electrical cords like

Electric grinders

- Lower upfront cost

- Slower, less powerful, and less practical for bigger spaces

Why Forte Emphasizes Preparation

At Forte Garage Floor Coating, the focus is on delivering results that hold up. The right CSP ensures coatings resist peeling, especially in high-use areas like garages. By relying on professional grinding equipment, the prep work sets the stage for coatings that last.

Bottom Line

In simple terms:

- Proper concrete prep is the foundation of a strong garage floor coating.

- CSP 3–4 is the “sweet spot” for adhesion.

- Grinding, especially with propane equipment, is the best way to achieve it.

- Skipping this step almost guarantees problems down the road.

If you’re getting your garage floor done, find a contractor who speaks this language. Anything less and you’re at a high risk of finding your shiny new floor peeling and cracking in a fraction of the time compared to having it done correctly the first time.

Save yourself the hassle! Quality garage floor coatings can last over 20 years.