If you’re serious about building a garage workshop in the Akron or Cleveland area, your flooring matters more than you think. Bare concrete may seem tough—but it can turn every project into a safety risk or cleanup nightmare. With high-performance hybrid epoxy and polyaspartic garage flooring from Forte Garage Floor Coating, you can avoid the most frustrating hazards DIYers face.

1. Damage from Dropped Tools and Equipment

One dropped hammer on bare concrete can chip the surface. GFC’s hybrid epoxy and polyaspartic garage flooring is impact resistant, which means dropped tools won’t leave permanent damage.

2. Chemical Spills That Stain and Soak In

From motor oil to wood stain, most garage workshops involve harsh chemicals. On raw, porous concrete, spills seep in fast and leave permanent marks. GFC’s coating system includes a chemical-resistant surface that lets you wipe up messes before they become eyesores.

3. Slick, Slippery Conditions That Cause Falls

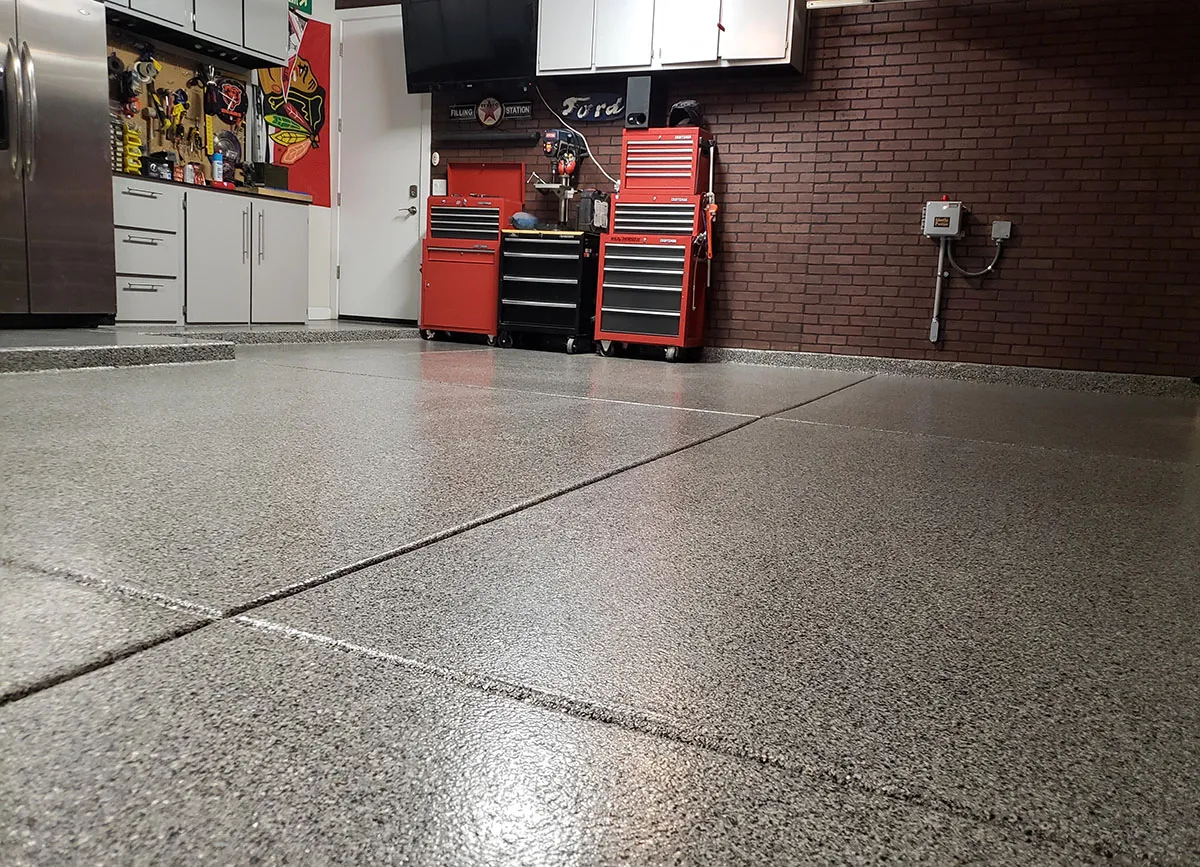

On poor quality garage flooring, ones with little to no anti-skid aggregate, dust, sawdust, and water can make a garage floor dangerously slick. GFC’s hybrid epoxy and polyaspartic garage flooring includes a built-in anti-skid texture that keeps your footing stable, even during messy projects.

4. Moisture That Creeps Up Through the Slab

In Northeast Ohio, seasonal moisture can turn your garage into a damp, musty space. Forte GFC’s coating systems include a high-build, 100%-solids, moisture-mitigating epoxy primer coat that acts as a moisture vapor barrier. It prevents moisture vapor pressure that wicks up from below, and the resulting high hydrostatic pressures, from ruining your floor.

5. Tire Marks That Don’t Go Away

If your workshop doubles as a garage, you know the frustration of hot-tire pickup (aka plasticizer migration). After one drive, you’ve got black tire stains that won’t come off. Forte GFC’s dual 100%-solids polyaspartic topcoats prevent hot-tire transfer, keeping your garage floor clean even after a hot summer drive.

Forte’s 2-Day System Delivers Lasting Results

Unlike 1-day systems that use a thin, fast-curing polyurea or polyaspartic base coat, Forte Garage Floor Coating uses GFC’s superior 2-day installation system. We apply a thick, slow-curing, moisture-mitigating epoxy base coat on Day 1 that acts as a moisture vapor barrier.

We then broadcast your selected flake blend into this primer coat in a thick, full flake spread. We return on day 2 to apply two separate 100%-solids polyaspartic topcoats (not just 1!). This process ensures better adhesion, better durability, and a better workshop experience—now and for years to come.

Ready to eliminate the five worst hazards of a concrete workshop floor? Contact Forte Garage Floor Coating today and upgrade your garage flooring for good.