ONE-DAY SYSTEMS: FASTER ISN’T BETTER

Concrete coating systems have become very popular. Because of this, many new concrete coating companies are trying to capitalize. Many of them are jumping onto the one-day polyurea systems or one-day polyaspartic systems bandwagon. Why? Because customers are attracted to the promise of a quick one-day installation…it’s simply less disruptive. To do this, one-day systems contractors use fast-curing coating products (polyureas or polyaspartics) to get the installation completed in a single day. But as with most things in life, “faster” isn’t “better”. GarageFloorCoating.com, which has been installing concrete coatings since 1996, touched on this in an August 2020 article called Polyurea-Polyaspartic One-Day Systems: Do They Work.

What are Polyurea and Polyaspartic Coatings?

One-day systems installers use liquid coating products called “polyureas” or “polyaspartics” as both their primer coats and clear top coats. They espouse the benefits of the fast-cure properties of these liquid coatings (and try to convince buyers that they’re “the best” or the “most advanced”). Albeit, they do have some excellent properties, and a fast cure rate is one of them. This allows them to install floor coatings in one day…where slower curing products would force a longer installation duration.

But what’s the difference between a polyurea and polyaspartic?

A polyurea is a coating with an extremely short cure time (it cures in seconds) that’s durable enough to coat roofs, foundations, truck beds, and other surfaces. The cure time is so short, in fact, that “true” polyureas require specialized equipment to apply it, like portable reactors.

A polyaspartic is a chemically-modified polyurea…called an “aliphatic polyurea”. It’s a polyurea that’s been chemically modified to cure slower, so it’s more user-friendly; that is, it can be applied with a simple roller in lieu of specialized equipment. So whether the contractor is selling you a one-day polyurea or one-day polyaspartic system…it’s essentially the same thing. It’s just a modified, slower-curing polyurea. (Albeit, “slow” is relative, as a polyaspartic still cures faster than an epoxy).

So What’s Wrong with “1-Day Systems”… A Lot!

The polyurea (or polyaspartic…whatever your contractor decides to call it) used in coating systems has a “fast-but-not-too-fast” cure rate. For applicators, this is good because it’s more user-friendly. In addition, polyurea-polyaspartics provide extreme UV, chemical and impact resistance. Also good.

But polyurea-polyaspartics have one major Achilles heel. They’re simply not meant to be applied direct-to-concrete, especially under high-moisture concrete conditions. Why? Because high-moisture permeating through porous concrete (called moisture-vapor transmission or MVT) creates high hydrostatic pressures which will push a thinly-applied polyurea-polyaspartic coating away from the concrete slab (it will peel or “delaminate”). So why not just apply a thicker coat? Because you can’t. The thickness at which a polyurea-polyaspartic can be applied, unlike an epoxy, is limited by the way in which it cures chemically. You can’t apply a polyurea-polyaspartic thickly…it simply won’t cure. And the thin, poor-concrete-penetrating polyurea-polyaspartic primer coat that one-day systems contractors apply isn’t sufficient to protect the floor against high hydrostatic pressures. That’s bad.

Cue the Epoxy Primer

An epoxy cures through an exothermic reaction (the reaction generates heat). The amount of heat depends on the thickness of the epoxy mass or the exposed surface area of mixed epoxy. A thicker mass retains more heat, causing a faster reaction and even more heat. So epoxies can be applied very thickly (they can be used as ‘high-build” primers), allowing them to resist high hydrostatic pressures. This makes an epoxy far better as a primer coat where concrete moisture is present. Polyurea-polyaspartics are excellent clear top coats….but lousy as direct-to-concrete primer coats.

1-day contractors know this.

So what do they do? They add a warranty exclusion to their contracts against “moisture-related issues”. When your 1-day coating delaminates due to high hydrostatic pressure, they simply invoke this warranty exclusion. Almost every “1-day polyurea” or “1-day polyaspartic” coating system out there will incorporate this warranty exclusion (in small print) in the customer contract. Buyer beware!

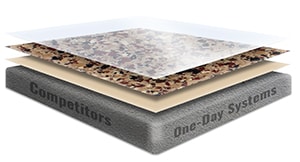

What Do 1-Day Systems Consist Of?

1-day systems typically consist of 3 layers: (i) a thin polyurea-polyaspartic primer coat applied direct-to-concrete (remember, it has to be thin), (ii) a full broadcast of thermoplastic flakes, and (iii) a single polyaspartic clear top coat. All three layers are applied in quick succession because of the quick cure rate of the polyurea-polyaspartic primer coat and clear top coat.

But there’s a proper way to apply concrete coatings that uses the best properties of epoxies and polyurea-polyaspartics.

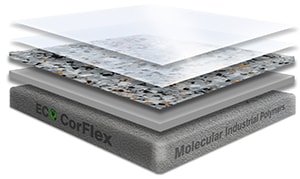

Experienced contractors will never use a polyurea-polyaspartic direct-to-concrete. Instead, they apply a thick layer (a “high-build”) of a moisture-mitigating epoxy as the primer. The polyurea-polyaspartic is only used as the clear top coat…and 2 coats are applied to produce an even thicker and more resilient coating. But because the moisture-mitigating epoxy primer has a slower cure rate, at least slower than a quick-cure polyurea-polyaspartic, the installation takes up to 2 days…not 1. It’s a slower installation process, but the final product is of far greater quality…significantly less likely to delaminate. Why play Russian roulette?

Then There’s Us

But we take it a step further. Forte Garage Floor Coating only applies industrial-grade concrete flooring. We apply our proprietary, moisture-mitigating, 100%-solids epoxy as the primer (not a polyaspartic). We then broadcast your selected chip blend. And like no other contractor, we offer an array of stunning mica-infused chip blends that take your flooring next-level. We then top it all off with two coats…not one…of our clear 100%-solids polyaspartic. For our full-chip coating system series, the result is a 35+-mil thick garage floor coating that’s guaranteed against all moisture-related conditions. (We have an entire line of industrial-grade polyaspartic-aliphatic polyurea coatings…and we use them in every garage…as clear tops coats. Never as direct-to-concrete primers!)

Want one-of-a-kind, industrial-grade, full-chip mica-stone infused garage floor coatings with a real warranty? Call Forte Garage Floor Coating at (330) 587-5222 for your free estimate.